Your home is exposed to severe levels of wind driven rain zones three or four in our map below your home is located in an unsheltered position eg not protected by trees or other buildings.

Cavity wall insulation beads problems.

Damp could occur in properties as a result of cavity wall insulation if there is a combination of these factors.

Polystyrene beads are produced to a specified size and density which remains unaltered during the.

Until recently dampness problems caused by cavity wall insulation have not generally occured in houses where the insulation was built in from new although this is now changing and the first acounts of dampness caused by built in cavity batts are starting to come in.

Incorrectly installed cavity wall insulation causes water to seep into a property s walls causing structural problems and damp patches that may also manifest into mould.

Any air gap between the insulation and the wall on the warm side of the cavity causes thermal looping.

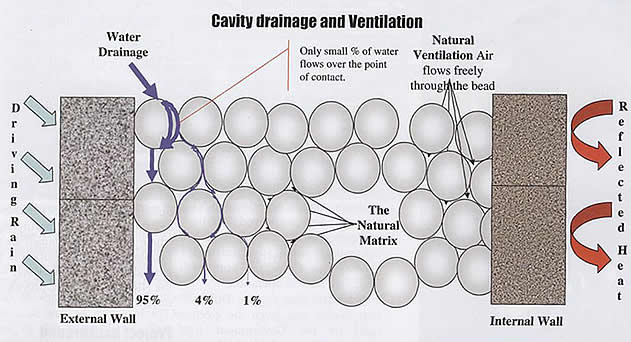

The gaps that naturally occur between the spherical beads allow any water to drain down freely to the ground rather than across to create damp problems on inside walls.

Benefits of blown bead.

Most people don t understand that problems with cavity wall insulation can also be down to defects in the building itself.

Plus driving rain can get through a well maintained facing brick wall.

If you live in zone 1 or 2 on the map below then you are at less risk.

In some cases the damp and mould resulting from cwi can cause health problems or exacerbate existing conditions particularly respiratory conditions.

If your wall is in poor condition i e.

Thermal looping happens when there s an air gap between the insulation boards and the inner leaf of blockwork this leads to heat getting drawn from the inside of the house into the cavity.

Problems are therefore extremely rare but if they do occur ciga has the expertise to ensure that they are swiftly rectified.

The problem is that this fills the cavity with a material that can allow water to cross the cavity causing dampness and if the material is not evenly distributed cold spots where insulation is missing can attract condensation.

The polystyrene used for cwi is in the form of virgin pre formed bead which is usually combined with a binding agent or adhesive at the time of injection.

The structure of the installed blown bead allows the cavity to retain the ability to breathe as intended with the cavity wall insulation in place.

The process seems simple drill into the outer wall inject a fibre or bead insulation into the cavity make good the holes sit back and enjoy reduced energy bills.

Cracking to render spalled blown bricks etc.

Probably the biggest cavity wall insulation problem is driving rain if you live in a an area which is exposed to driving winds then you are at a higher risk of moisture penetration.